More productive and selective catalysts are the objective of the new Collaborative Research Center 1333 at the University of Stuttgart, which the German Research Foundation (DFG) approved in its senate session on 17th May 2018. This now makes the University of Stuttgart the head institution of five Collaborative Research Centers and three Transregios.

Rector Professor Wolfram Ressel was delighted to comment on the success: “With the speaker role in now eight Collaborative Research Centers and Transregios, the University of Stuttgart once again confirms its position as an excellent research university as well as the strength of the Stuttgart Way of interlinked disciplines. In the projects of the new Collaborative Research Center it is the expertise of the University of Stuttgart in its strategic research field of simulation sciences as well as in materials sciences in particular that is contributed along with the competences and analysis methods from the Faculty of Chemistry as well as the Max Planck-Institute of Solid State Research.“

Collaborative Research Center 1333 Molecular heterogeneous catalysis in confined geometries

Speaker: Professor Michael R. Buchmeiser, Institute of Polymer Chemistry, University of Stuttgart, Tel. +49 711 685-64075, Email

Whoever paid attention in chemistry lessons knows it: catalysts are compounds that accelerate chemical reactions and ensure that the desired product is created in a more targeted and quicker way. Catalytic processes thus save resources, energy and ultimately a lot of money as well. The chemical and pharmaceutical industry uses it for over 80 percent of its products – from packaging materials such as polypropylene to fertilisers up to the well-known painkiller Ibuprofen.

Yet catalysts are not an invention of the chemical industry. In nature they have always been the driving force behind many processes essential to life, for example yeast fermentation. A particularly successful concept, which up to now has only succeeded satisfactorily in nature, is the targeted use of cavities to control the catalysis. The Collaborative Reseach Center 1333 now wants to apply this concept to chemical catalysts.

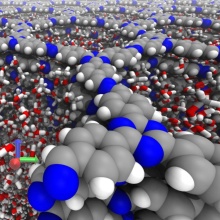

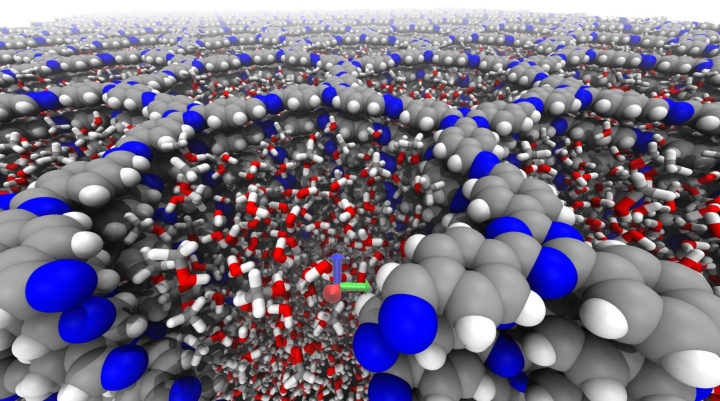

The scientists' starting point is molecular heterogeneous catalysis, a chemical process in which a soluble catalyst is bound to a solid carrier material via a linker and thus is available as a solid material, i.e. heterogeneous in the reaction solution. One challenge of this procedure is to bind as many catalyst molecules per gram carrier material as possible. This works with the aid of porous materials that have particularly large surfaces. The process, however, is hardly used because up to now in most cases the interactions of the catalyst with the carrier material have had a negative influence on its productivity. Furthermore one cannot precisely foresee which reactions are actually accelerated (selectivity).

Biocatalysts in contrast, always have a defined cavity around their active center, as a confining reaction environment and through this achieve excellent selectivities and productivities. Several effects are responsible for this: for example the concentration of the source materials can be increased in the area of the catalytic center. In addition, the restricted space can lead to the reactants only being bound in a certain way to the catalyst or by-products of the reaction being removed in an accelerated manner.

In order to fundamentally understand these effects and to make them useable for chemical catalysts, scientists from catalysis, materials sciences, physics, simulation sciences as well as analytical chemistry are working closely together in the Collaborative Research Center. Synergies are also to be expected through the close link to the Excellence Cluster Simulation Technology (Simtech) as well as to the existing Collaborative Research Center 1313 at the University of Stuttgart dealing with transport processes in porous media. The aim is to develop tailored catalyst carrier hybrids with improved productivity and selectivity for each reaction. This can also open up access to challenging chemical transformations, such as those between gases, liquids and solid materials, and catalytic reactions with notoriously unreactive molecules such as dinitrogen or carbon dioxide.