With three new testing facilities, the Forschungsinstitut für Kraftfahrwesen und Fahrzeugmotoren Stuttgart (Research Institute of Automotive Engineering and Vehicle Engines Stuttgart, or FKFS) and the Institute for Internal Combustion Engines and Automotive Engineering (IVK) at the University of Stuttgart are systematically focusing on technologies for the cars of the future. On Thursday, May 23, 2019, the new test benches were inaugurated and went “into action” for the first time.

Electromobility, hybrid drives, automated and autonomous driving. The three ultra-modern new additions to the institute’s array of test benches contribute towards the development and testing of these technologies for contemporary and future mobility. They were jointly developed and realized by the FKFS and IVK – a process in which countless innovative approaches from both institutes played a part. On May 23, research and testing operations officially began at the testing facilities, which in part are unique in Europe. “For the institutes, these investments – after the extensive refurbishment of the wind tunnel in 2014 and several extensions and new buildings at the Pfaffenwaldring site in Stuttgart – are an additional milestone in their strategic focus on the mobility of tomorrow”, says Prof. Hans-Christian Reuss, CEO at FKFS and director at the IVK.

High-performance electric powertrain test bench

The new high-performance electric powertrain test bench (HEP), with two wheeled machines and a drive machine, is highly flexible and built to test complete e-drives or individual components. The HEP was designed to pioneering specifications in order to meet the future requirements for electric powertrains in terms of performance, rotational speeds and voltages. This is why the test items are powered by a powerful battery simulator for voltages of up to 1,000 volts. Dynamic load tests and durability testing can also be carried out at the new test bench, as well as the drive application and function development. In addition to this, efficiency and system measurements can be represented using high-precision power measurement technology and the parameter identification of e-machines. The new test bench will also enable widely available drives to be tested in automated vehicles under realistic load spectra and failure scenarios.

Hybrid engine test bench

The hybrid engine test bench has two roles, which help it contribute towards meeting CO2 emissions targets. On one hand, the new hybrid engine test bench is fitted with loading systems which simulate combustion engines in hybrid operation, including a system for analyzing emissions to ensure they meet legal requirements. On the other hand, the electric powertrain can be used to test powerful electric loads under pressure, whereby different measurement techniques are used to analyze limited pollutants online. This means that the new hybrid engine test bench can be used to test and assess the emissions of hybrid powertrains at a very early stage. The institutes are also able to depict the entire development processes of hybrid systems, from the function development, the modeling of raw emissions behavior and the effectiveness of implementing the exhaust after treatment system to the parameterization and validation of the finished system under “steady state” conditions, both in the legal and real test cycles.

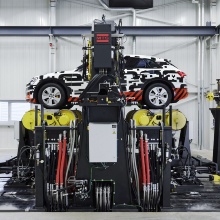

Vehicle dynamics test bench

The new vehicle dynamics test bench is synonymous with a modern and highly innovative test concept, which is the first of its kind in Europe. This makes it possible to inspect transverse, longitudinal and vertical dynamic vehicle characteristics under laboratory conditions for the first time – and not just in isolation, but also as a whole with a detailed and reproducible view of the interactions. This opens up a broad range of applications for current and future technologies, from supporting traditional test drives to testing the interaction between new types of drive and chassis concepts. So for example, assistance systems, active steering and chassis systems or integrated vehicle dynamic control systems can be further developed, tested and certified. The new test bench also makes it possible to test functions from the Advanced Driver Assistance System (ADAS) or autonomous driving under safe conditions.

About the FKFS and University of Stuttgart

The Forschungsinstitut für Kraftfahrwesen und Fahrzeugmotoren Stuttgart (Research Institute of Automotive Engineering and Vehicle Engines Stuttgart, or FKFS) is one of the best-known German development service providers, and works closely together with the Institute for Internal Combustion Engines and Automotive Engineering (IVK) at the University of Stuttgart. The FKFS employs around 180 highly-qualified staff and operates a number of state-of-the-art testing facilities, including an ultra-modern vehicle wind tunnel, a driving simulator, engine test benches and a powertrain test bench.

The University of Stuttgart, founded in 1829, has around 26,000 students. Its vision of “Intelligent systems for a sustainable society” and its distinctive “Stuttgart method” stand for consistent interdisciplinary networking of complimentary specialist disciplines as well as integrating engineering, science, humanities and social studies.