Corynebacterium glutamicum has been named "Microbe of the Year 2025" in recognition of its significant industrial importance. And rightly so, say researchers from a DFG priority program coordinated by the University of Stuttgart: Research on the microbe has been underway since 2019 as part of “InterZell”.

Corynebacterium glutamicum, the bacterium named Microbe of the Year 2025 by the Association for General and Applied Microbiology, is of great importance to the food, feed and pharmaceutical industries. C. glutamicum is known as a natural producer of glutamate - the seasoning agent that triggers the savory “umami” taste of food on the tongue. With the help of sugar, C. glutamicum produces many other important amino acids and active ingredients. This includes L-lysine, an essential amino acid vital for both the human body and many animals.

Biotechnological processes driven by microorganisms are the focus of the DFG priority program “InterZell", coordinated by the University of Stuttgart. Within the “InterZell” project SIMBAL, Prof. Alexander Grünberger (Karlsruhe Institute of Technology), Dr. Dietrich Kohlheyer (Forschungszentrum Jülich), and Prof. Andreas Schmid (Helmholtz Centre for Environmental Research Leipzig) are investigating the “Microbe of the Year.”

Using complementary co-culture systems

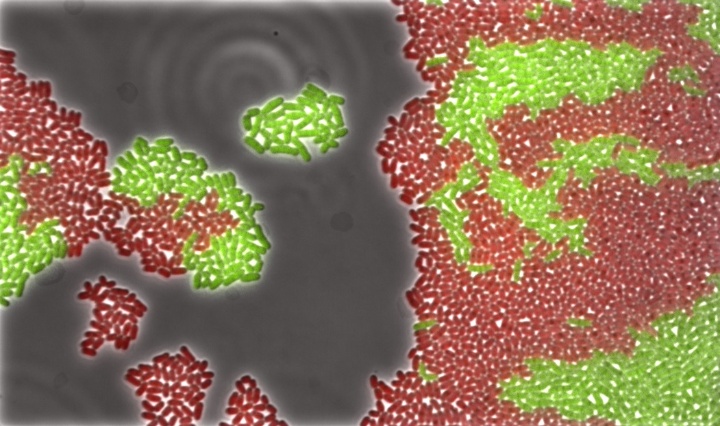

Using C. glutamicum as a model, the team is exploring how different microorganisms interact at the single-cell level within a controlled environment. “We use two strains of Corynebacterium glutamicum as complementary co-culture systems. Each strain is auxotrophic for a specific essential amino acid, meaning it is unable to synthesize it on its own. In the co-culture, however, one partner supplies the other with this required amino acid. This is the only way both can grow,” says Prof. Alexander Grünberger from KIT. “The aim is to control and use such microbial “partnerships” to gain new knowledge about the biotechnological production process at cell level,” says Prof. Andreas Schmid. “Our experiments provide important tools and findings for this. They enable the development of novel, single-cell biocatalysts for strain and process development for bioprocesses with pure and mixed cultures.”

Based on their experiments, the researchers are also developing a model to optimize physical and biochemical parameters during industrial scale-up. “Growing volumes of data also present us with challenges in biotechnology. Models for fully automated image analysis of microbial time-lapse images can be used to better characterize individual cells. This gives us benchmarks for investigating biological phenomena,” says Dr. Dietrich Kohlheyer.

“InterZell": Sustainable research into biotechnological processes

SIMBAL is one of ten projects in the DFG priority program “InterZell” coordinated by the University of Stuttgart. As part of “InterZell”, 50 scientists from various institutions are researching current issues in bioprocess engineering. They are not only focusing on C. glutamicum, but also on other microorganisms that play an important role in industrial biotechnology. The researchers combine microbiology, molecular biology, cell cultivation and cell biology with engineering principles such as system modeling, process development and simulation.

“Many active ingredients can now be efficiently produced through biotechnology, using microorganisms such as bacteria,” says InterZell coordinator Prof. Ralf Takors from the Institute of Biochemical Engineering at the University of Stuttgart. “However, scaling up for large-scale production is still a challenge. This is where “InterZell” comes in. We are researching new biotechnological production processes in the laboratory - i.e. on a small scale and with low material input. Based on the insights we gain during this process, we can develop models and information on upscaling in industrial production. This research approach is efficient and saves resources.”

The bacterium of the year 2025: Corynebacterium glutamicum

Every year, the Association for General and Applied Microbiology (VAAM) selects a “Microbe of the Year”. With this initiative, the VAAM draws attention to the important role of microorganisms for ecology, health, nutrition and the economy. With C. glutamicum, the VAAM 2025 has selected a microbe of great industrial importance. C. glutamicum plays a key role in industrial biotechnology. The microbe of the year 2025 produces amino acids and proteins for the food, feed, and pharmaceutical industries.

C. glutamicum is being studied not only within the DFG priority program InterZell but also by Prof. Ralf Takors and his team at the Institute of Biochemical Engineering at the University of Stuttgart, who have been researching C. glutamicum since 2009. The focus is on industrial biotechnology, aiming to sustainably utilize previously untapped raw materials from three generations: First-generation (refined sugar), second-generation (sugar from residual materials like lignocellulose), and third-generation (CO2 and waste gases) for the production of biofuels and bioproducts.

Publication: Food for Thoughts for Prospective Biomanufacturing

The DFG priority program “InterZell”

“InterZell” is a network of ten research projects involving a total of 50 scientists from eleven universities and research institutions. The German Research Foundation (DFG) is funding the priority program for a total of six years.

Project website

Instagram

Podcast “Lab Whispers about Bioengineering“

Expert Contact:

Prof. Dr.-Ing. Ralf Takors, Dr. Martina Rehnert

Coordination of the DFG priority program “InterZell”, University of Stuttgart, Institute of Biomedical Engineering, Phone: +49 711 685 69925, Email

Contact

Lena Jauernig

Editor Research / Early Career Researchers