Lightweight concrete construction without waste

Visible from afar in the Giardini della Marinaressa, a public park in the center of Venice, the "Marinaressa Coral Tree" has been impressing visitors to the Architecture Biennale since May. The filigree concrete sculpture was designed by Daria Kovaleva and Prof. Lucio Blandini from the Institute for Lightweight Design and Conceptual Design (ILEK) at the University of Stuttgart. It shows how innovations in planning, materials technology and manufacturing can contribute to a sustainable transformation of the construction industry. The installation is the result of a collaboration between the ILEK and the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) at the University of Stuttgart.

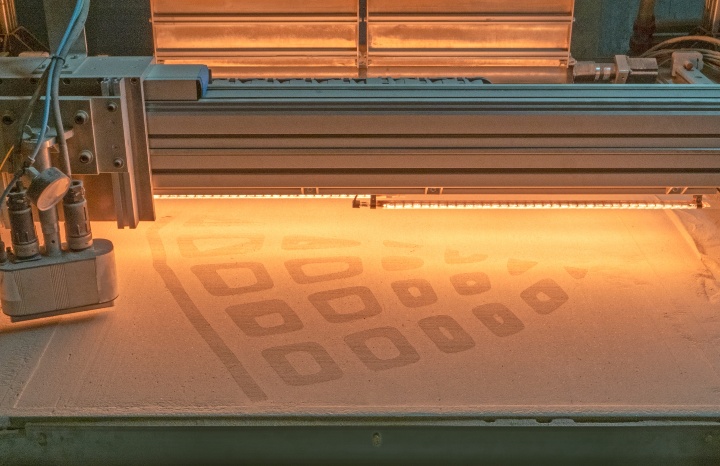

The structure originated from a research project on the sustainable production of lightweight concrete components using waste-free sand formwork. Lightweight construction principles can significantly reduce material usage, as well as emissions associated with construction - even in concrete construction. However, the complex geometries associated with lightweight construction principles, such as multi-curved surfaces, can so far only be produced in concrete with a great deal of work and large quantities of waste.

And that's why the project focused on the development of a production technology for waste-free manufacturing of complex shaped concrete structures by using recyclable sand formwork. The production of these formworks is based on a combination of additive manufacturing (3D printing in a powder bed) and a specially developed mixture of sand and an organic water-soluble binder. The 3D printing system was developed specifically for the project by Maximilian Nistler, research assistant at ISW under the supervision of Prof. Alexander Verl.

The Marinaressa Coral Tree is an impressive example of the potential of this technology. The filigree structure is a reinterpretation of the traditional ceiling-to-column transition, in which loads are transferred from the horizontal ceiling to the columns via the capital. Thanks to the optimum distribution of the material in line with the stress curve, material consumption has been reduced by 60 percent compared with conventional structures - with the same load-bearing capacity. In terms of the environmental impact of the construction industry, such holistic lightweighting principles are of great importance for sustainable concrete construction, as they can significantly minimization resource consumption, emissions, and waste.

Biomaterials as a design tool

With no less than three exhibits - 3DNaturDruck, LeichtPRO and the Smart Circular Bridge - the Department of Bio-based Materials and Material Cycles in Architecture (BioMat) of the Institute of Building Structures and Structural Design (ITKE) at the University of Stuttgart is participating in the Architecture Biennale and is also cooperating with the ILEK. The BioMat exhibition "Materials as a Design Tool" showcases projects that advance the application of biomaterials in the built environment. The aim is to create a circular economy in line with the Sustainable Development Goal of the United Nations.

3DNaturDruck investigates the architectural application of 3D-printed natural fibers. Through interdisciplinary research, this project seeks to co-design a new materialization process by connecting the fields of architectural design, engineering, and digital fabrication. The column demonstrator Ligno Print presents a viable strategy by which this emerging material method may be applied to large-scale architectural scenarios; new territory for this particular natural fiber technique.

LeichtPRO explores the development of lightweight construction profiles and components using renewable raw materials, with the ultimate goal being sustainability. Two products are created: The newly developed natural flax fiber profiles produced through the pultrusion technique and biocomposite connectors. Both are intended for application in structural systems. The LightPRO Shell pavilion from 2021 showcased a large-scale lightweight active-bending shell structure. Further applications have also been realized, such as a supporting structural system and other shell structures.

The Smart Circular Bridge demonstrates the potential of a bioeconomy in the construction industry. The project includes the construction of three biocomposite pedestrian and bicycle bridges in Europe. A sophisticated monitoring system continuously monitors the stability and material condition. This ensures not only the highest level of safety for use, but also provides extensive information for planning further bridges. Aiming at maximum material circularity, the recovery of the biocomposite materials is also included in the research.

Further information:

The Venice Architecture Biennale will take place from May 20 to November 26, 2023. The concrete structure can be seen in the Giardini della Marinaressa in front of the Arsenale. The Biomat exhibition is located in Palazzo Mora, 2nd floor, Strada Nova, 3659.

| Contact | Prof. Lucio Blandini, Universität Stuttgart, Institut für Leichtbaue Entwerfen und Konstruieren (ILEK), Tel. +49 711 685 61760, Email Assoc.-Prof. Hanaa Dahy, Universität Stuttgart, Institut für Tragkonstruktionen und Konstruktives Entwerfen (ITKE), Abt. BioMat, Tel. +49 711 685 83274, EMail |

|---|