Air filters in buildings are not only an important element in pandemic control, they also protect sensitive technical components from contaminants such as ultra-fine particles, viruses, and germs. Depending on the filter medium used, the devices consume a lot of energy. Against the backdrop of rising energy costs and the need to reduce CO2 emissions worldwide, this is increasingly coming into focus. The joint research project NANOFIL of the University of Stuttgart and the filter manufacturer MANN+HUMMEL now wants to optimize the microstructure of filter media and make the devices more efficient. To achieve this, the researchers rely on simulation science.

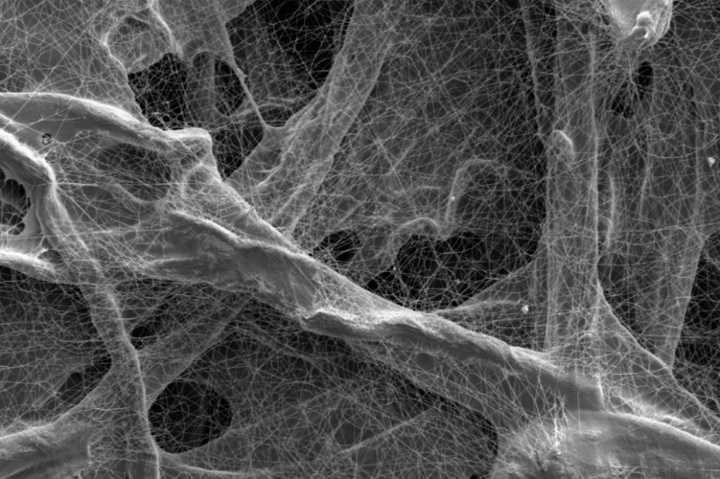

At the heart of stationary building ventilation systems are highly efficient filter media with an appropriate particle separation performance, which can be achieved, in particular, by using ultra-fine synthetic, glass, or nanofibers. In addition to a high separation performance, air filter media require the lowest possible pressure drop in order to reduce energy consumption. If the performance of a filter medium can be predicted with respect to these factors, its microstructure can be optimized in a targeted manner to meet specific requirements.

However, this requires a sufficiently accurate mapping of the effects that occur in this process. “To ensure the validity of the predicted material properties, we need to consider the behavior of trillions of particles in our calculations,” explains Prof. Carsten Mehring from the Institute of Mechanical Process Engineering (IMVT), who is managing the project at the University of Stuttgart. “When developing filter media for specific applications, simulation is therefore a valuable tool.”

In particular, there are currently no application-oriented model approaches for the processes involved in the separation of ultra-fine particles on ultra-fine fibers. The main objective of NANOFIL is, therefore, to improve the simulation models that are already established in the virtual development of filter media and to extend those models with regard to nanofibers. For this purpose, and in particular to take into account the effects that have been neglected so far, suitable submodels are being developed, which will then be integrated into an overall simulation model. The improved model will first be validated extensively before demonstrating its suitability for application. “Our goal is to use simulation models to predict the processes in an optimized, nanofiber-coated air filter medium as accurately as possible,” says Mehring. The filter medium will then be produced and its performance tested.

About NANOFIL

The collaborative project NANOFIL (Optimization of the Separation and Energy Efficiency of Innovative Air Filter Media in the Micron and Submicron Range by Using Improved Model Approaches) is funded by the Federal Ministry of Economic Affairs and Climate Protection with about EUR 963,000 for three years (funding code 03EN2081B). The project starts on June 1, 2022.

Expert Contact:

Prof. Dr. Carsten Mehring, University of Stuttgart, Institute of Mechanical Process Engineering (IMVT), phone:+49 711 685 85361, E-Mail