Chitin is the main component of the exoskeletons of insects, spiders, and crustaceans and ensures, for example, that an insect exoskeleton is both robust and flexible. A research group led by Prof. Sabine Laschat at the University of Stuttgart wants to use chitin and its derivatives to develop materials in a water-based process that are suitable for special applications in the construction industry to reduce energy consumption in a sustainable manner. The Carl Zeiss Foundation is supporting the project with about EUR two million as part of its “Perspectives” funding line.

As a polymer, chitin is widespread in nature and has fascinating mechanical and optical properties that scientists would like to make technically usable. Chitin-based materials would be particularly attractive because they are hydrophobic and, unlike cellulose-based materials, cannot absorb water, which makes them resistant to mold. In addition, they become fireproof through chemical modification, are mechanically very robust and, unlike synthetic polymers, are compostable.

However, the technical use of chitin so far is still in its infancy, as the polymer can only be modified (processed) in a solution with difficulty. Against this background, the project “Chitinfluid - Chitin as a Resource for Multi-Functional Materials via Water-Based Complex Fluids” aims to develop simple water-based processing of chitin and its derivatives into smart materials. These will initially be used in special applications in the construction sector, where they are intended to curb the enormous consumption of energy and resources and high CO2 emissions. Furthermore, chitin-containing hybrid materials are conceivable as photonic materials (e.g. as a substitute for effect pigments) or, in the case of fiber composites, as a substitute for carbon fibers. The automotive industry and many other sectors could benefit from this.

Proceeding step-by-step

A key challenge for the technical use of chitin is to transform it into a form that is, at the nanoscale, ordered but that can be processed as a fluid. This is to be investigated in several steps:

To begin with, the researchers want to “reprogram” the raw material chitin with the help of microorganisms, so that modified sugar monomers can be incorporated into the growing polymer chain and tailor-made chitin copolymers of modifiable structural and mechanical properties can be produced. These chitin derivatives are to be made processable via complex fluids (colloidal chitin solutions, lyotropic liquid crystalline solutions, and hydrogels). By means of controlled dehydration, mineralization, and blowing agents, the resulting complex fluids will be processed into solid foams, composites, or coatings with an adjustable bending stiffness that are suitable for additive manufacturing. Finally, first prototypes of innovative building materials and components are to be developed and optimization rules are to be defined, for example, for acoustic absorption, thermal insulation, and compostability.

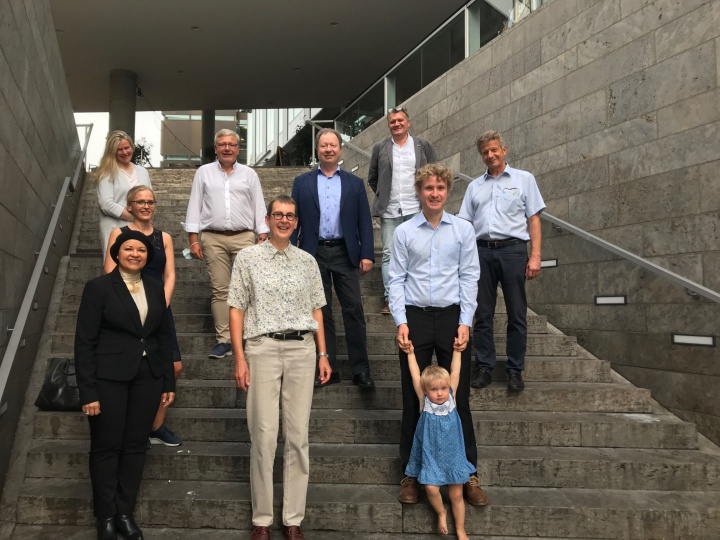

Seven scientists in six institutes

Since these research objectives can only be achieved in an interdisciplinary way, seven scientists from six institutes of the University of Stuttgart are contributing their core competencies to the project:

- Prof. Sabine Laschat (Spokesperson, Institute of Organic Chemistry): chemoenzymatic synthesis of organic functional molecules (ionic liquid crystals, carbohydrates)

- Prof. Hanaa Dahy (Institute of Building Structures and Structural Design, ITKE): building materials, components development, sustainability

- Prof. Harald Garrecht (Institute of Construction Materials & Materials Testing Institute, MPA): materials in civil and construction engineering, special concretes

- Prof. Frank Giesselmann (Institute of Physical Chemistry, IPC): soft matter, lyotropic liquid crystals

- Appl. Prof. Dr. Thomas Sottmann (IPC): complex fluids, production of porous bio-based materials.

- Dr. Linus Stegbauer (Institute of Interfacial Process Engineering and Plasma Technology, IGVP): chemistry of bio-inspired structural materials.

- Prof. Ingrid Weiss (Institute of Biomaterials and Biomolecular Systems): chitin biosynthesis & biomodification.

Characterization and application-oriented aspects are handled by the AMICA (Advanced Materials Innovation and Characterization) research network, a center for multi-scale material characterization and visualization at the University of Stuttgart.

In the current call for proposals, the Carl Zeiss Foundation, four research projects from the universities of Stuttgart, Konstanz, Mainz, and Jena have convinced the reviewers in a two-stage evaluation process and will be funded with EUR two million each. All projects investigate how new material compounds can make conventional materials “smarter”, adapt to new situations, and develop desired “behaviors”.

About the Carl Zeiss Foundation

The Carl Zeiss Foundation has set itself the goal of creating scope for scientific breakthroughs. As a partner in excellent science, it supports both basic research and application-oriented research and teaching in the STEM disciplines (mathematics, computer science, natural sciences, and technology). Founded in 1889 by the physicist and mathematician Ernst Abbe, the Carl Zeiss Foundation is one of the oldest and largest private foundations in Germany that promote science. It is the sole shareholder of Carl Zeiss AG and SCHOTT AG. Its projects are financed from the dividend payouts of the two foundation companies.

Expert Contact:

Prof. Dr. Sabine Laschat, University of Stuttgart, Institute of Organic Chemistry, phone +49 711 685 64268, E-Mail